Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts

| tem | Custom Manufacturer Silicone Mold Making Silicone Part Other Silicone Rubber Part |

| Material | EPDM, NBR, SBR, NR, Silicone(VMQ), Neoprene(CR), HNBR, XNBR, FKM, FFKM, FVMQ, FLAS, PTFE, PU, ECO, IIR, ACR, etc... |

| Silicone: High Tensile Silicone, Food Grade Silicone, Medical Grade Silicone, High Clear Silicone, etc. | |

| If there is any special requirements on material performance, such as temperature resistant, resists deformation, compression set, tensile strength etc... | |

| Foam material is also available. If you do not know what kind of material to use, pls advise us what is the usage of these parts? Then we can make some recommend for you. | |

| Certificate | IATF 16949:2016 / ISO 9001:2015 /REACH/ROHS/MSDS/LFGB |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Color | Almost all PMS colors available for Silicone (VMQ); Mostly black for other rubber materials, if other colors are required, please indicate it on inquiry. |

| Parameters | Inch, centimeter, millimeter, etc. |

| Function | Industrial parts /daily supply / Automotive/ Medical device, etc... |

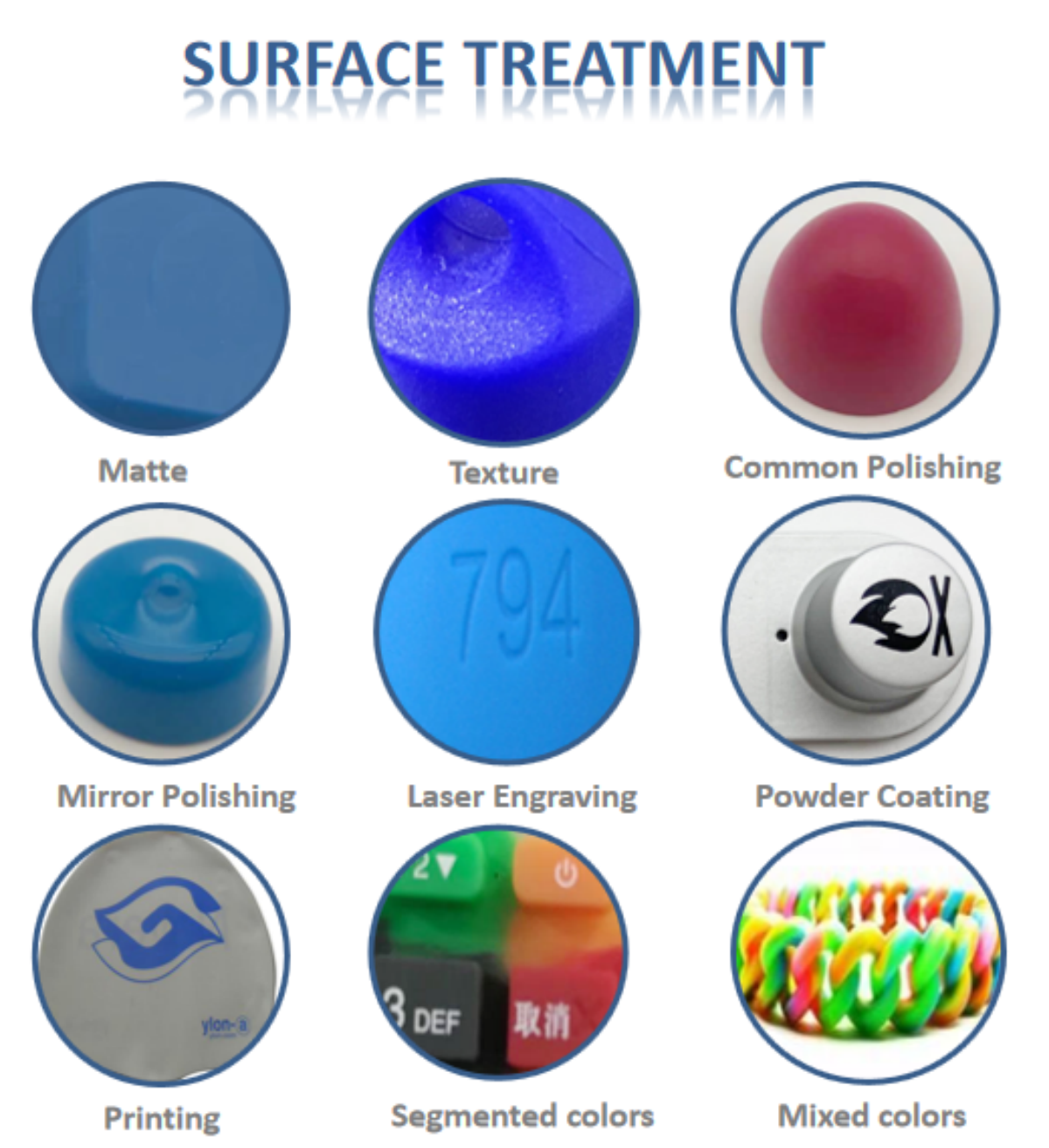

| Surface Treatment | Matte, Common polishing, Mirror polishing, Texture, Laser Engraving, Power Coating (Painting), Printing, Segmented colors, Mixed, colors, etc. |

| Mold Material | No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. |

| Mold Precision | If no special request, apply to ISO3302:2014 standards, class 2. |

| Mold Life-cycle | 100,000-500,000 shots. |

| Packing | Pack in bulk / poly bag / bubble bag / color box. |

| Sample | Available. One cavity sample mold or 3D printing. |

Please provide your drawings to customize for you.

Material Characteristics

Nitrile ( Buna-N) (NBR) General industrial use material for oil, grease and solvent resistance.

Silicone Excellent material for resistance to aging, heat, sunlight, many oils, and chemicals. Fluroelastomer (FKM) Excellent resistance to oils, fuels and solvents at higher temperature ranges. EPDM Excellent resistance to heat aging, ozone, acids, and alkalines. Neoprene General industrial material used with non-aromatic petroleum oils and greases.

Choose materials according to the usage, please find rubber properties chart bellow.

Any questions please contact us to get more details.

Nitrile ( Buna-N) (NBR) General industrial use material for oil, grease and solvent resistance.

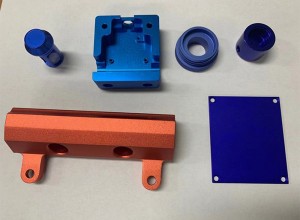

Some Custom Rubber Parts for Reference

Manufacturing Process

RCT Mold has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export.

You can choose your favorite surface finish

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Powder Coating, Printing, Segmented Colors, Mixed Colors), etc. You can view below surface pictures for reference:

RCT Mold highly welcome custom surface treatment for rubber parts.

Packing

RCT Mold package for rubber parts: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers.