Plastic Injection Mold Maker

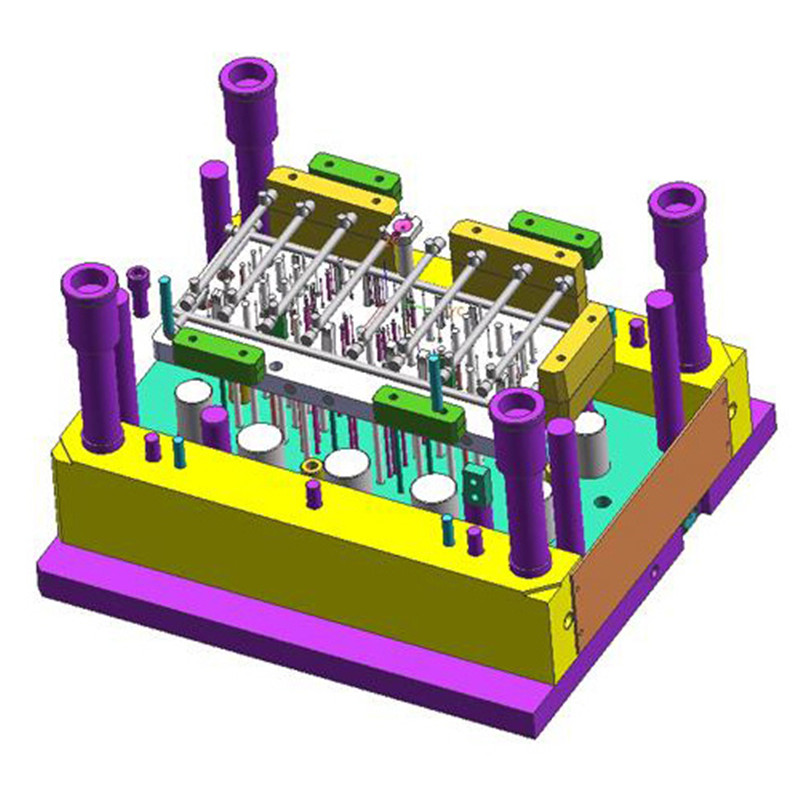

RCT MFG is ISO 9001:2015 certified and lean manufacturing. Custom plastic injection mold maker, manufacturing from hardened steel, pre-hardened steel, aluminum and beryllium copper alloys. Able to handle single part projects or multi-part projects and produce simple to complex close tolerance parts. Capabilities include part design and engineering, low volume and short run production, tooling, rapid prototyping and fast turnaround.

We can customize precision plastic injection molds including automotive molds, consumer tooling, spin-out plastic molds, high polish molds, overmolding molds, two-shot molds, insert molds and more.

One-stop plastic mold service

Mold Design

RCT MFG is an injection mold supplier with decades of experience in mold design. Our molds are precise, durable, and designed to be efficient in the manufacturing process.

Mold Making

We offer mold-making services at competitive rates and deliver in short lead times. All processes are performed under strict quality guidelines and the supervision of mold engineering experts.

Injection Molding

Our injection molding factory is fitted with ultra modern equipment that churns out hundreds of injection molding parts on demand. We use premium quality materials for every project.

Quality in Every Injection Mold and Molded Component

Commitment to quality is fundamental to RCT MFG’s production philosophy, and we apply rigorous standards at every step of the process to ensure consistently high-quality injection molds and parts.

From incoming raw material audits to final product inspections, our professional quality control inspectors adhere to established standards to meet your expectations.

Work with Our Experts for Customized Injection Molds and Products

Our team of designers and injection molding engineering experts are highly-qualified and well-experienced in their craft. They keep up with evolving injection moulding industry trends and are continuously innovating new cutting-edge solutions.

When you entrust us with your injection molding project, we handle it with utmost professionalism and dedication. Every design detail will be custom-made to match your requirements and ease your manufacturing process.

We guarantee you a stress-free customer experience and complete discretion on all intellectual property. Look no further. Contact us today and let us get started on your project.

Why do plastic injection molds cost so much?

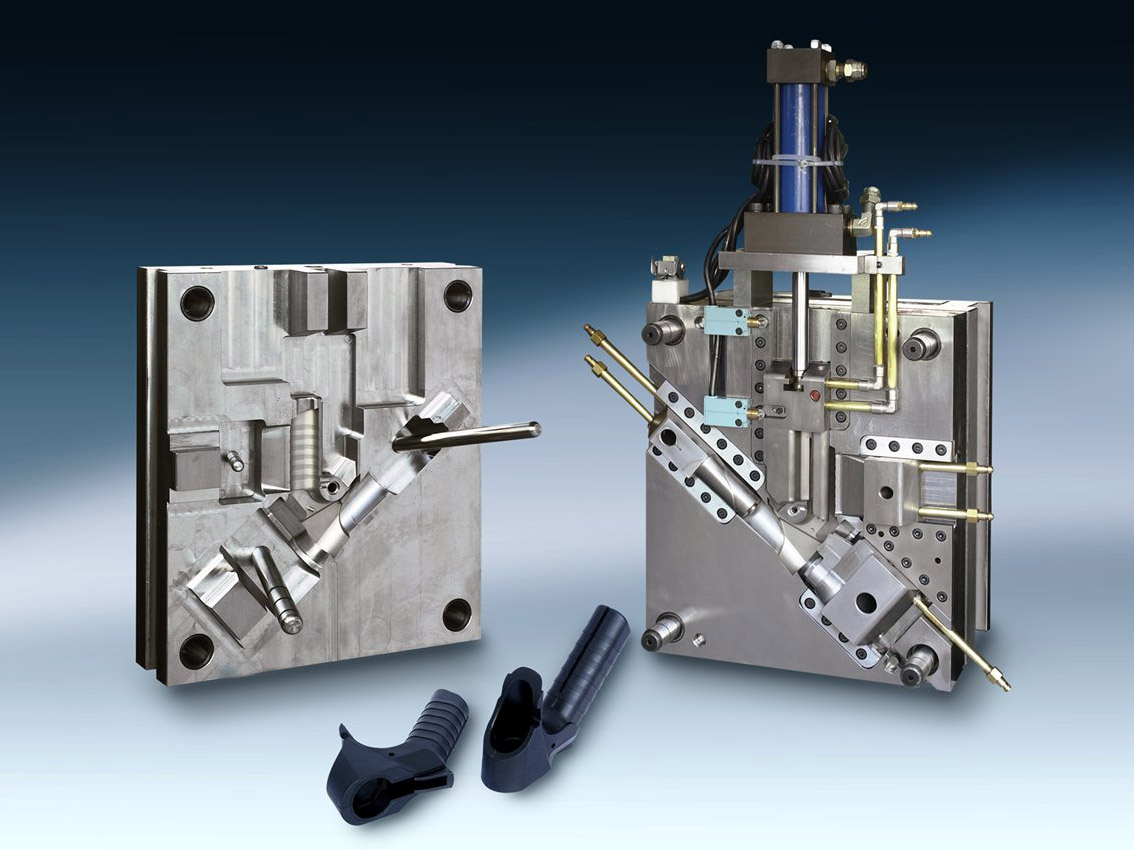

High-quality plastic parts can only be produced if you use high-quality molds. Plastic injection molds consist of precision-machined components made from a variety of metals, such as aircraft-grade aluminum or hardened mold steel.

These molds are designed and built by highly skilled and well-paid people who are collectively known as "mold makers." They spend years or even decades being trained in the mold making industry. In addition, mold makers need very expensive tools to do their job, such as very expensive software, CNC machinery, tooling, and precision fixtures. The time it takes a mold maker to complete a plastic injection mold can range from a few days to a few weeks, depending on the complexity and size of the final product.

Our Projects

RCT MFG is able to manufacture a wide range of molds, including overmolding molds, two-shot injection molds, 2K plastic injection molds, gas-assisted molds, hot runner molds, multi-cavity molds, insert molds, spin-out molds, MUD rapid prototyping injection molds, die-casting molds, fixtures, etc., which greatly enhances our expertise in plastic injection mold manufacturing.