A good product is not only processed, but also requires various surface treatments to achieve corrosion resistance, wear resistance, aesthetics, and increase service life. RCT MFG has many years of experience in CNC processing and injection molding processing, also provides a series of services from processing to surface treatment to assembly. Therefore, in addition to fabrication technology, it also has rich experience in surface treatment. The existing surface treatment processes include: painting, Baking paint, powder coating, sandblasting, shot blasting, anodizing, thick film anodizing, micro-arc anodizing, electroplating, electrophoresis, laser engraving, silk screen printing, brushed metal, mirror polishing, dyeing, blackening, CD pattern, etching, high gloss, etch pattern , Epoxy, etc., help to make your products in a high level.

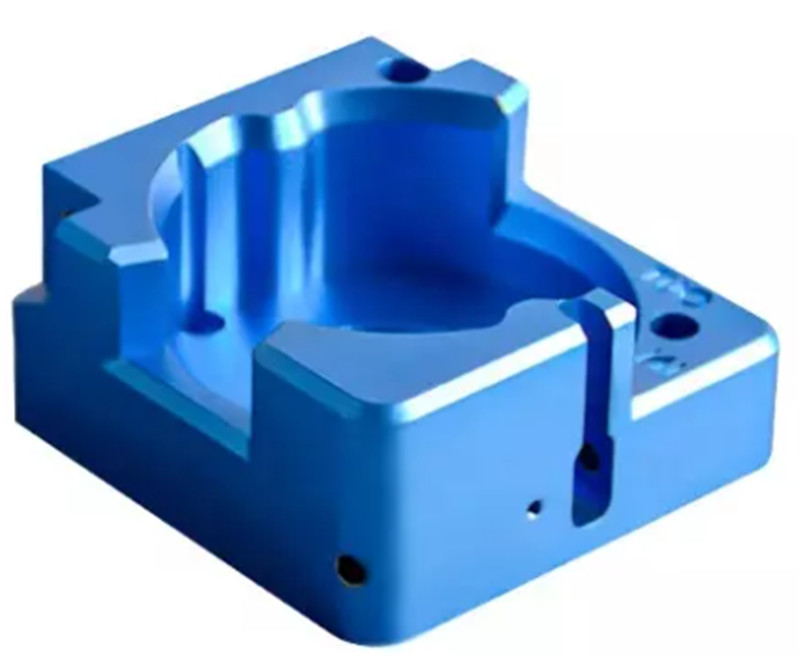

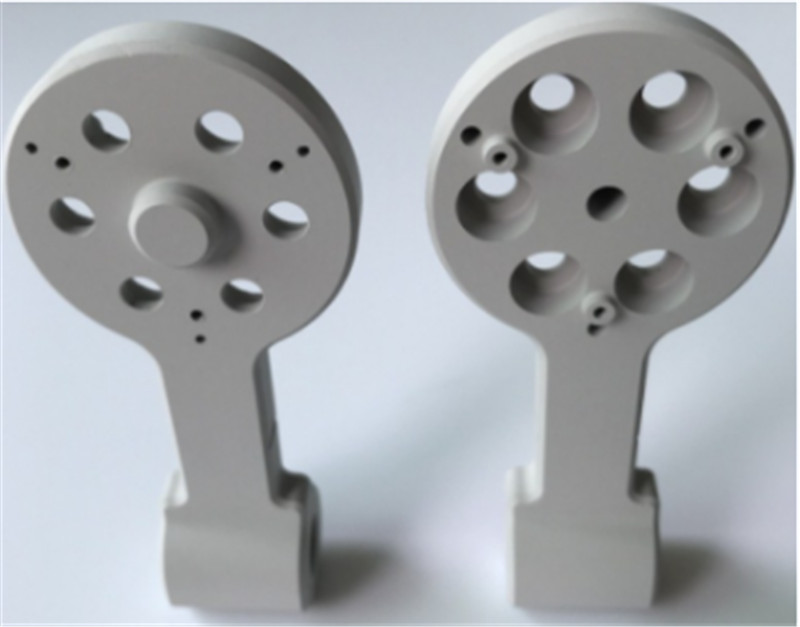

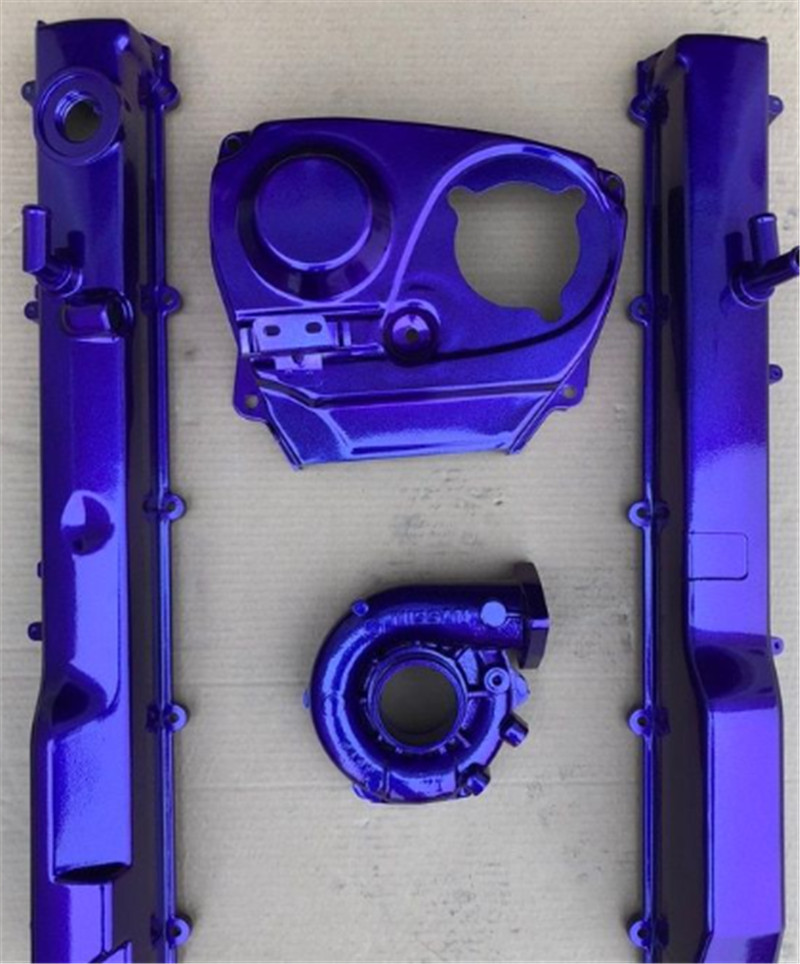

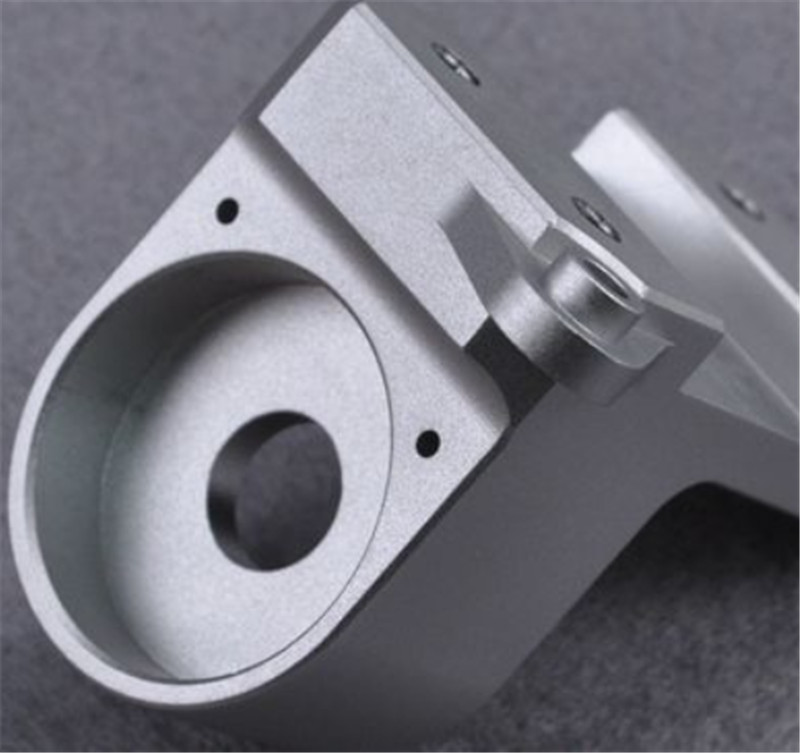

Anodizing

It is an electrolytic oxidation process, which converts the surface of the material into a protective film, making it difficult to oxidize and corrode, prolonging the life and achieving the appearance of various colors. Commonly used anodizing treatments are divided into: common anodizing , brushed metal anodizing, hard anodizing, thick film anodizing, micro-arc oxidation, etc. The materials that can be oxidized are: aluminum alloy, magnesium alloy, titanium alloy, etc.

Electroplating

The basic process of electroplating is to immerse the part in the solution of metal salt as the cathode, and the metal plate as the anode, and pass the current to deposit the desired coating on the part. The appropriate electroplating effect will make your product more high-end fashion and with it. To a better market, standard electroplating includes copper plating, nickel plating, silver plating, gold plating, chrome plating, galvanizing, tin plating, vacuum plating, etc.

Electrophoretic coating

With the continuous improvement of industrial demand, Electrophoretic coating technology can customize various colors, maintain metallic luster and enhance the corrosion resistance of the surface, which has little impact on product accuracy. The thickness is about 10-25um, and thicker ones are also Can be customized

Passivation

Passivation, also known as chromate treatment, is a pickling process that removes surface grease, rust, and oxides by immersion or ultrasonic cleaning. Through the chemical reaction of the passivation solution, it can prevent corrosion and prolong rust. The color of the passivation film will change with different materials. Passivation will not increase the thickness of the product, and there is no need to worry about it affecting the accuracy of the product.

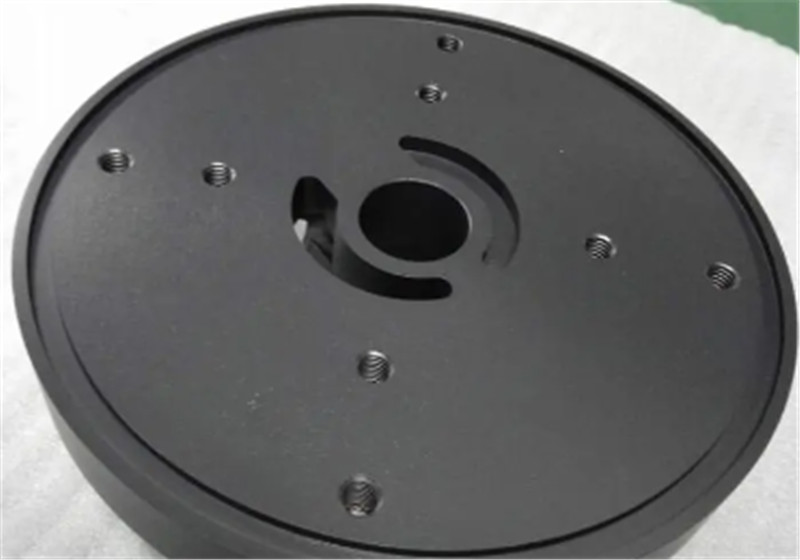

Blackened

Blackening is also called bluing. The principle is to immerse the product in a strong oxidizing chemical solution to form an oxide film on the metal surface to isolate the air and achieve the purpose of rust prevention. This process is applicable to steel materials.

QPQ (Quench-Polish-Quench)

It refers to putting ferrous metal parts into two kinds of salt baths with different properties, and infiltrating various elements into the metal surface to form a composite infiltration layer, so as to achieve the purpose of modifying the surface of the parts. It has good wear resistance, fatigue resistance, corrosion resistance and small deformation. This process is applicable to all steel materials.

(Note: Stainless steel products cannot be blackened, and the surface can only be blackened by QPQ)

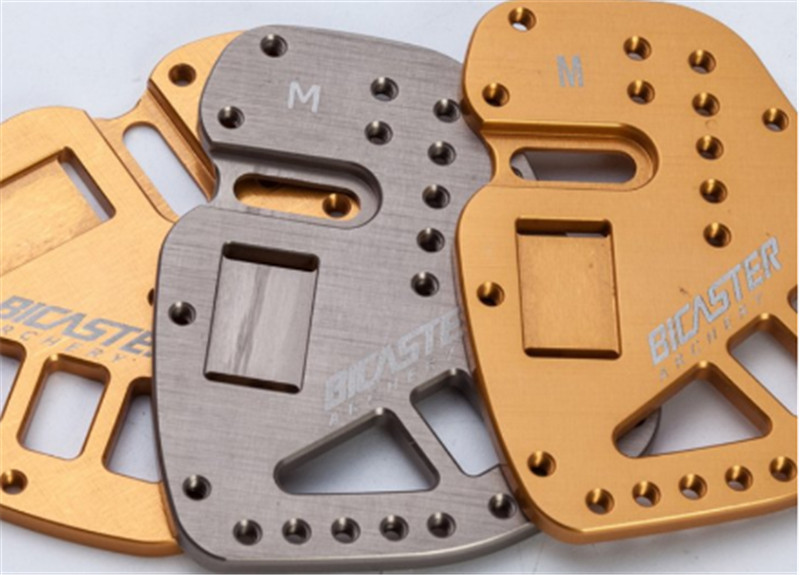

Laser engraving

Laser engraving, also called laser marking, is a surface treatment process using optical principles to form LOGO or patterns on products. The laser engraving effect is permanent, the surface quality is high, and it is suitable for products made of various metal and plastic materials

Silk screen printing

Silk screen printing means that the ink transfers the pattern to the product through the screen. The color of the ink can be customized according to the needs of customers. RCT MFG has done 6 colors on the same product, including black, red, blue, yellow and white. ,green. If you want the effect of silk screen printing to be more durable, you can also add a layer of UV after silk screen printing to prolong its life. Silk screen printing is suitable for various metal and plastic materials, and can also be combined with surface treatment such as oxidation, painting, powder spraying, electroplating, and electrophoresis.

Polishing

Polishing is to make the product beautiful, translucent and protect the surface. Polishing and transparency is a good choice for you. The polishing of hardware products is divided into manual polishing, mechanical polishing, and electrolytic polishing. Electrolytic polishing can be used to replace heavy mechanical polishing, especially for parts with complex shapes and parts that are difficult to process by manual polishing and mechanical methods. Electrolytic polishing is often used for steel, aluminum, copper and other parts.

Brushed Metal

Brushed metal is a surface treatment method that forms lines on the surface of the workpiece through a flat-pressed abrasive belt and a non-woven roller brush to achieve a decorative effect. Brushed surface treatment can reflect the texture of metal materials, and it is becoming more and more popular in modern life. It is widely used in mobile phones, computers, monitors, furniture, electrical appliances and other shells.

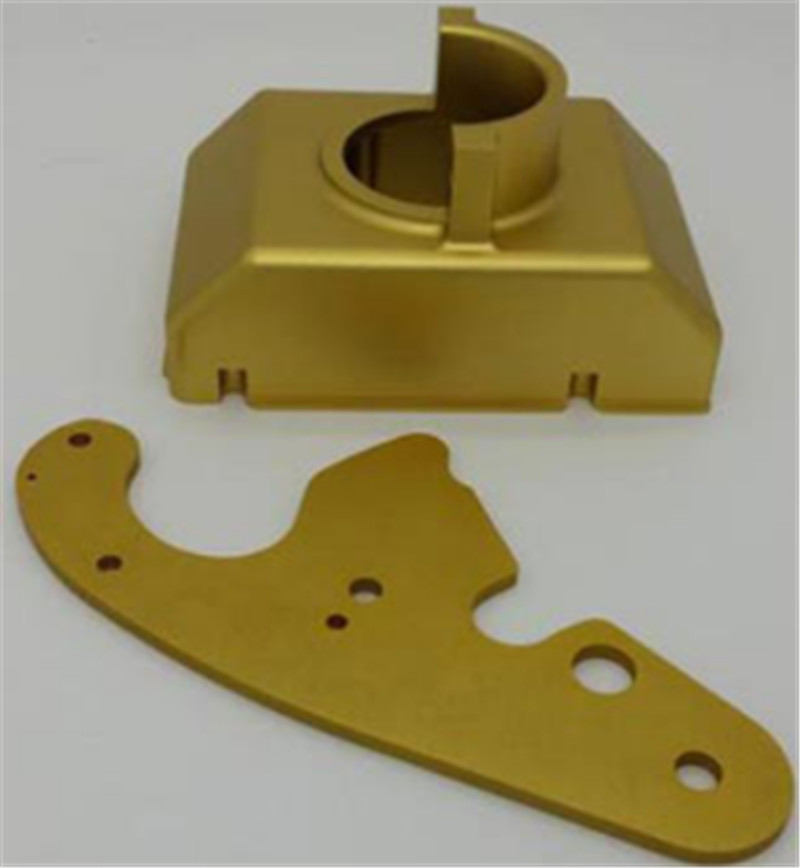

Paint spraying and powder spraying

Paint spraying and powder spraying are two common surface treatments in hardware parts spraying, and they are the most commonly used surface treatments for precision parts and small batch customization. They can protect the surface from corrosion, rust, and can also achieve an aesthetic effect. Both powder spraying and painting can be customized with different textures (fine lines, rough lines, leather lines, etc.), different colors, and different gloss levels (matte, flat, high-gloss).

Sandblasting

Sandblasting is one of the commonly used surface treatments for hardware products. It can improve the cleanliness and roughness, and increase the adhesion and durability between the product and the coating. Therefore, many surface treatments choose sandblasting as their pre-treatment. Such as: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + paint, sandblasting + passivation, etc.

Teflon spraying

Also called Teflon spraying, it is a very unique surface treatment. It has superior characteristics of anti viscosity, non viscosity, high temperature resistance, low friction, high hardness, non wetness, and high chemical resistance. Therefore, it is widely used in food industry, tableware, kitchenware, paper industry, medical equipment, electronic products and automobile products, chemical equipment, etc., and can protect materials from chemical corrosion to extend the service life of products.

Etching

Etching is the technique of removing material using chemical reactions or physical impact. Usually refers to etching, also known as photochemical etching, which refers to removing the protective film of the area to be etched after exposure plate making and development, and contacting chemical solution during etching to achieve the effect of dissolution and corrosion, forming the effect of concave-convex or hollow molding.

IMD

In Mold Decoration (IMD) is a cost effective method of decorating plastic parts. It consists of four steps: Printing, Forming, Trimming and Injection Molding. And It is an internationally popular surface decoration technology. The surface is hardened and transparent film, the middle printing pattern layer, the back injection molding layer, and the middle of the ink can make the product resistant to friction. , prevent the surface from being scratched, and can keep the color bright and not easy to fade for a long time.

Pad Printing

Pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a silicon pad takes a 2-D image from a laser engraved (etched) printing plate (also called cliché) and transfers it to a 3-D object. Thanks to pad printing, it is now possible to print all kinds of difficult shaped products such as curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc. which were not available with traditional printing processes.

Water transfter printing

Water transfer printing is a kind of printing that uses water pressure to hydrolyze the transfer paper/plastic film with color patterns. The technological process includes the production of water transfer printing paper, soaking the flower paper, pattern transfer, drying, and finished product.

Conductive coating

Conductive coating is a kind of paint that can be used for spraying. It can conduct electricity after drying to form a paint film, so as to shield electromagnetic interference. At present, it is used in many military and civil industrial fields such as electronics, electrical appliances, aviation, chemical industry, printing, etc

Post time: Apr-11-2023