Black spots or black inclusions in the molded parts are an annoying, time-consuming, and costly problem. The particles are released when starting production and before or during regular cleaning of the screw and cylinder. These particles develop when material carbonizes due to overheating, which may occur when the material flow is stopped for a longer time without reducing the temperature in the machine.

The Causes of Black Spots

Resin decomposition

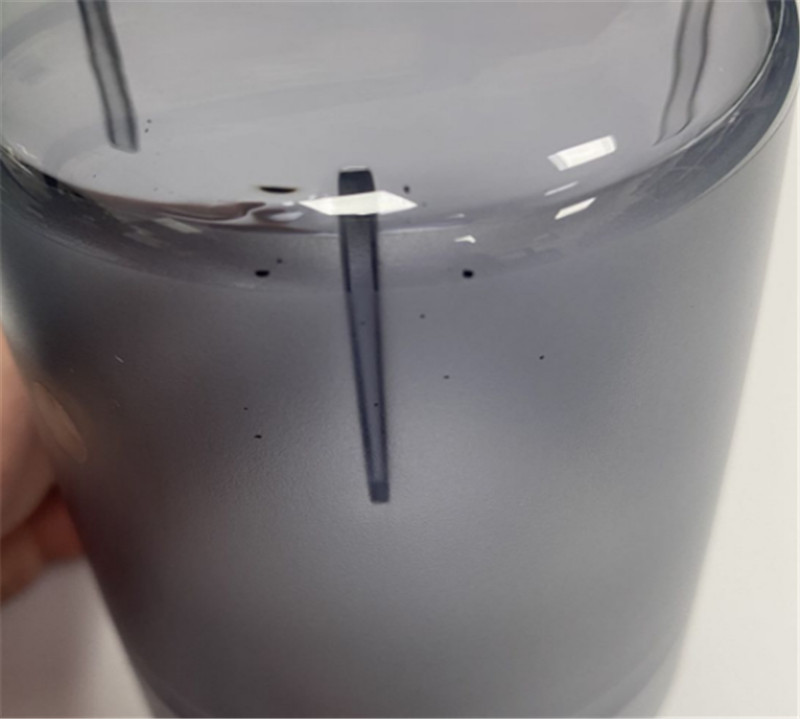

Since plastic material is a chemical, it gradually decomposes when it continues to be heated above the melting point. The higher the temperature and the longer the time, the faster the decomposition proceeds. In addition, inside the barrel, there are areas where the resin is easily retained, such as the check non-return valve and the screw thread. The resin that remains in these parts will be charred or carbonized, and then falls off rhythmically to mix into the molded product, thus causing the black spots.

Insufficient cleaning

The fact that the previously used resin remains in the molding machine due to insufficient cleaning is also a cause of black dots. As described in the above paragraph, since there are areas where the resin is easily retained, such as the check ring and the screw thread, it is necessary to apply a corresponding intensity and times of cleaning to these areas during a material change. In addition, a cleaning method suitable for each material must be employed. It is relatively easy to carry out the cleaning for similar resins, such as PC→PC, but if it is a cleaning of different kinds of materials, since the melting point or decomposition temperature is different, while compatibility (affinity) exists between the resins, it cannot be completely removed in many cases despite cleaning.

Mixing of foreign substances (contamination)

Contamination is also one of the causes of black spots. If some of the pellets fed into the hopper are mixed with other resins having a lower decomposition temperature, black spots may be easily caused due to the decomposition of the resin. In addition, attention should be paid to recycled plastics. This is because recycled plastic is more prone to decomposition after being heated many times (the greater the number of repeated recycles, the longer the heating time). In addition, it may be contaminated with metal during the recycling process.

The Solutions for Black Spots

1. First, wash thoroughly until black spots no longer appear.

Black spots tend to stay in the check ring and screw thread in the barrel. If black spots have ever appeared, it is estimated that the cause of them is likely to remain in the barrel. Therefore, after black specks appear, the barrel must be thoroughly cleaned before taking countermeasures (otherwise black specks will never disappear).

2. Try to lower the molding temperature

Various resins have recommended application temperatures (the catalogue or product package also contains this information). Check if the set temperature of the molding machine is out of range. If so, lower the temperature. In addition, the temperature displayed on the molding machine is the temperature of the area where the sensor is located, which is somewhat different from the actual resin temperature. If possible, it is recommended to measure the actual temperature with a resin thermometer or the like. In particular, the areas that are prone to resin retention, such as the check ring, are most likely to cause black specks, so pay special attention to the temperature in the vicinity.

3. Reduce the residence time

Even if the set temperature of the molding machine is within the recommended temperature range of various resins, long-term retention may cause deterioration of the resin and thus the appearance of black spots. If the molding machine offers the delay setting feature, please take full advantage of it, and also select a molding machine suitable for the mold size.

4. Contamination or not?

Occasional mixing of other resins or metals may also result in black specks.

What is surprising is that the cause is mostly inadequate cleaning. Please perform the work after thoroughly cleaning and removing the resin used in the previous injection molding run. When using the recycled plastic, check with the naked eye to see if there is the presence of foreign substances in the pellets.

Post time: Apr-11-2023