Our Services

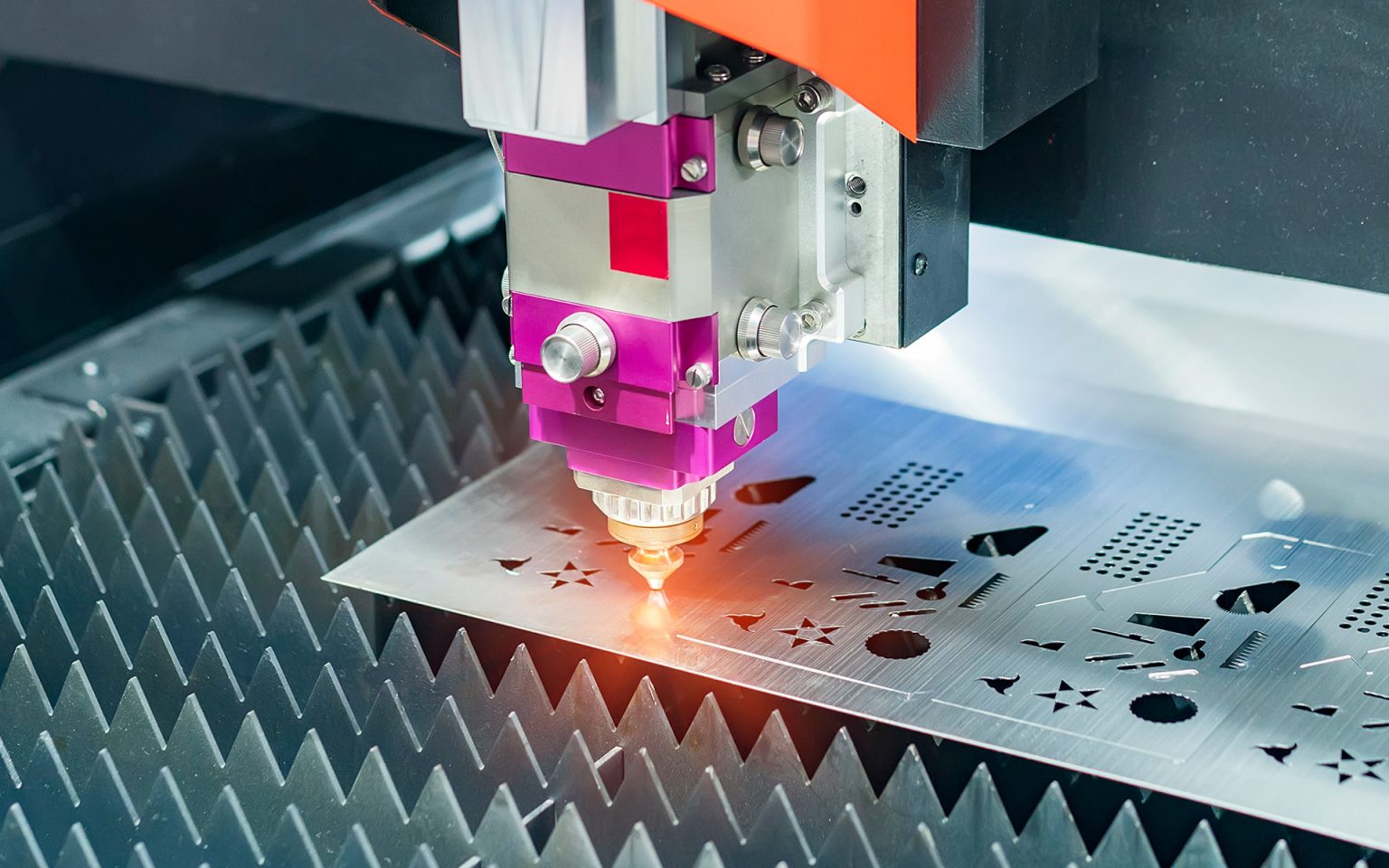

RCT MFG offers high-quality metal laser cutting services. Our metal laser cutting services support a wide range of metal materials including: steel, stainless steel, tool steel, spring steel, aluminum, brass, bronze, copper and titanium. Our laser cutting machines use fiber lasers and CO2 lasers and can cut metal materials up to 4 inches thick. For more information, see our metal laser cutting services page or go ahead and start a quote today.

Laser Cut Metal General Tolerances

| Description | General Tolerance |

|---|---|

|

General Tolerances |

For full details on tolerances offered by RCT MFG's sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

|

Thickness Dimension |

Thickness tolerances are determined by the material blank. |

|

Minimum Recommend Part Size |

1.000" |

|

Minimum Feature Size |

2X material thickness with a minimum of 0.062" |

|

Kerf (slit size) |

Approximately 0.020" |

|

Edge Condition |

Laser cut parts will have a vertical striation on the cut face. |

Benefits of Laser Cutting Services

The laser cutting process offers several advantages over traditional mechanical cutting or CNC machining processes, including faster production, less workpiece contamination, and less chance of warping. Laser cutting machines produce clean laser cut parts with minimal operator error, making them ideal for rapid prototyping.

RCT MFG’s custom laser cutting services provide cost-effective, on-demand solutions for your sheet metal fabrication needs, including the material, detail, and size of your project. From quick, low-volume prototypes to high-quality, high-volume production runs, RCT MFG has the ideal shop and the ideal machine.

What is laser cutting?

Laser cutting is a process where a high power laser light beam is used to cut through materials. The material either melts, burns or vaporizes by the laser beam, leaving a clean edge. Laser cutting is a precise process and can be used to cut simple and complex shapes, for metal cutting or laser engraving.

Laser metal cutting is the new standard for cutting 2D parts from large sheets of raw materials. Online laser cutting services offer a convenient way to have materials cut by a laser. Laser-cutting steel is one of the most popular applications of this technology. A laser cutting company can cut many materials for sheet metal fabrication of small and large production runs.

Types of Lasers used in Laser Cutting

Mainly four types of lasers are used for cutting: CO2, fiber, neodymium (Nd), and Nd:YAG lasers. CO2 lasers are the most common lasers due to their high energy and efficiency. CO2 lasers are suitable for use with engraving and cutting.

RCT MFG primarily uses fiber laser cutters since they offer several advantages over other types of laser cutters, such as increased speed, increased accuracy, and lower power consumption. Additionally, fiber lasers are much more durable and require less maintenance than other types of laser cutters. Fiber lasers also generate less heat during the cutting process, which eliminates the need for cooling systems. These factors and benefits make them ideal for custom machining since they are accurate, reliable, and cost-effective for the machine shop, resulting in lower manufacturing costs for part designers and engineers.

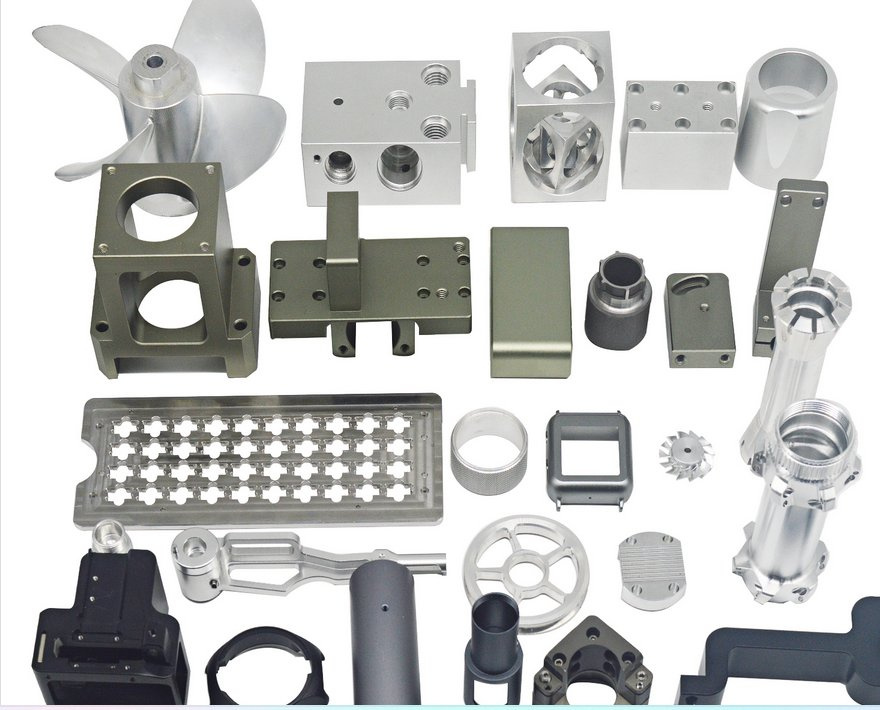

Secondary Machining for Laser Cut CNC Parts

Many CAD model designers utilize secondary machining processes with laser cutting such as metal bending, tapping, and surface finishing. For metal bending, the CAD model designer can indicate the placement and desired angle of bends or tapping instructions in a laser cut part design file. After the custom parts have finished production they are sent to hydraulic press brakes for bending or to tapping machines. The majority of materials typically used in CNC laser cutting are also able to get surface finishing such as anodizing, powder coating, painting, polishing, or media blasting. This allows the custom laser cut parts to have a uniform look, added functionality, corrosion protection, or just be more cosmetically appealing. The use of these secondary machining services with laser cutting provides CAD designers more capabilities to get their custom parts into production.