High precision injection molds industrial machine injection mould

| Part Material | PC |

| Mould Cavity | 2 Cavities |

| Mould Cavity Steel | 2344 (HRC48-52) |

| Mould Injection System | Hot runner |

| Mould Ejection System | Ejector pin |

| Mould Cycle Time | 30's |

| Mould Life Cycle | 500,000 shots |

| Lead Time | 4 weeks |

| Mould base | Customized |

| Product | Auto Parts Mould |

| Certification | ISO9001:2015 |

| Mold export to | Europe |

| Mould Maker | Shenzhen RCT MFG |

What's high precision injection mold?

High precision injection molding is a process of manufacturing parts with extremely tight tolerances, typically in the range of thousandths of an inch. The process involves injecting molten plastic into a mold cavity with extremely tight tolerances, using high-pressure injection molding machines. The molds used in this process require a high level of precision and accuracy as they must be able to produce parts that meet strict dimensional requirements and ensure consistency across multiple production runs. High precision injection molds are commonly used in industries such as medical devices, electronics, and aerospace where exacting tolerances and precise part dimensions are crucial.

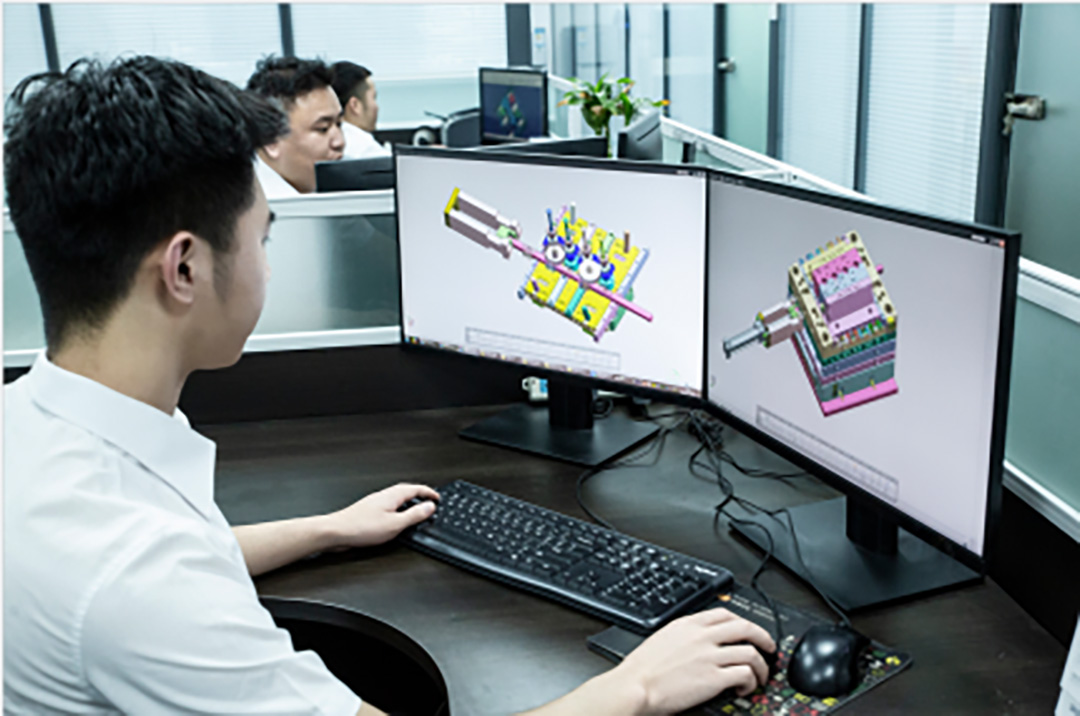

RCT MFG is an expert in the design and manufacture of high-quality plastic injection moulds and injected moulded parts offered specifically for the international market. We offer OEM/ODM production which strictly follows the mould quality standard from our customer demand. Our commitment to servicing our customers with quality products at competitive prices and on-time delivery is backed by our continued investment in equipment, employees, and management system.

Our mould making capacities and experiences include:

● Family mold

● Multiple cavity mold

● Interchangeable insert molds

● Molds with Multiple Sliders /lifters mechanism

● Molds with floating core

● Hot Runner System mold

● Unscrewing mechanism Molds

● Die-casting

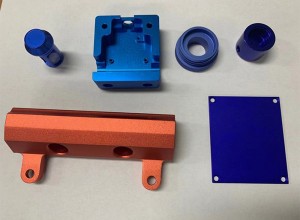

High precision injection molds

| Items | Description |

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Hardness of steel | 46~56 HRC |

| Molud Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mould Base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| Cavity | Single/Multi |

| Runner | Hot/Cold Runner |

| Maximum Mould Size | 1500*1500 mm |

| Surface of Mould | EDM / High Polish&Texture |

| Plastic material | PC, PC+ABS, ABS, PBT, LCP, PBT+GF, POM, Nylon, PEEK, PE, HDPE, PP, AS, PS, PP+PULVISTALCI, PET, TPU, PPS, PSU, PPO |

| Mould Life | 0.3 Million Shots- 1Million shots (Different steel different production, min mold life 200, 000 shots) |

| Specification | Depends on customer’s requirements. |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

| Trade terms | FOB Shenzhen ,EXW ,CIF |

| Export to | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| Hot Runner system | MOLD-MASTERS, INCOE, HUSKY , SYNVENTIVE, YUDO, EVIKON etc. |

| Mold cold runner | point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Surface finish of Part | Logo print,Texture,Polishing,Painting,Chrome Plating |

| Delivery time | 4weeks to 7weeks |

| Measurement Tools | 3D Measurement, Profile Projector, Hardness Tester and other regular size inspection equipment. |

| Outside package | Standard wooden cases or as your requirement |

| Inner package | Stretch waterproof film & Each Mold painted ,anti-rust oil. Spare parts together with the mold shipment. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

Injection Mold maintenance and after-services

"All of the plastic injection molds manufactured and stay at RCT Mold for injection molding is well organized to put on storage after molding production is finished, Core and cavity would be covered by anti-rust spray, mold plate would be clean without any mess, it would be labeled and identified to easy to accesses for next time production, we ensure it’s immediately available whenever you are in need of more plastic parts, Any changes of the features and molds will be recorded and traceable."

All of the injection molds for export are delivered with 2D/3D design drawings, NC programming data, injection parameters, measurement reports, etc, we also provide EDM copper, interchangeable inserts, and wearing parts for the accessible worn-out area, this will ensure you to do maintenance or replacement at your facility very easy.

Contact Us Today to start your injection mold projects

We provide quality parts at reasonable prices, this is the reason why the customers choose us instead of our competitors

We have different engineers Including design, manufacturing, quality control and sales, all are skilled and professional with plastic mold standards and injection molding.

Contact our team now and we will never let our customers leave without 100% satisfaction, let us be your reliable and reputable plastic mold partner.

Mold machining Machines