Custom Aluminium enclosure sheet metal fabrication

| Place of Origin: | Guangdong, China |

| Brand Name: | aluminium cover |

| Model Number: | sheet metal enclosure |

| Product name: | Custom Aluminium enclosure sheet metal fabrication |

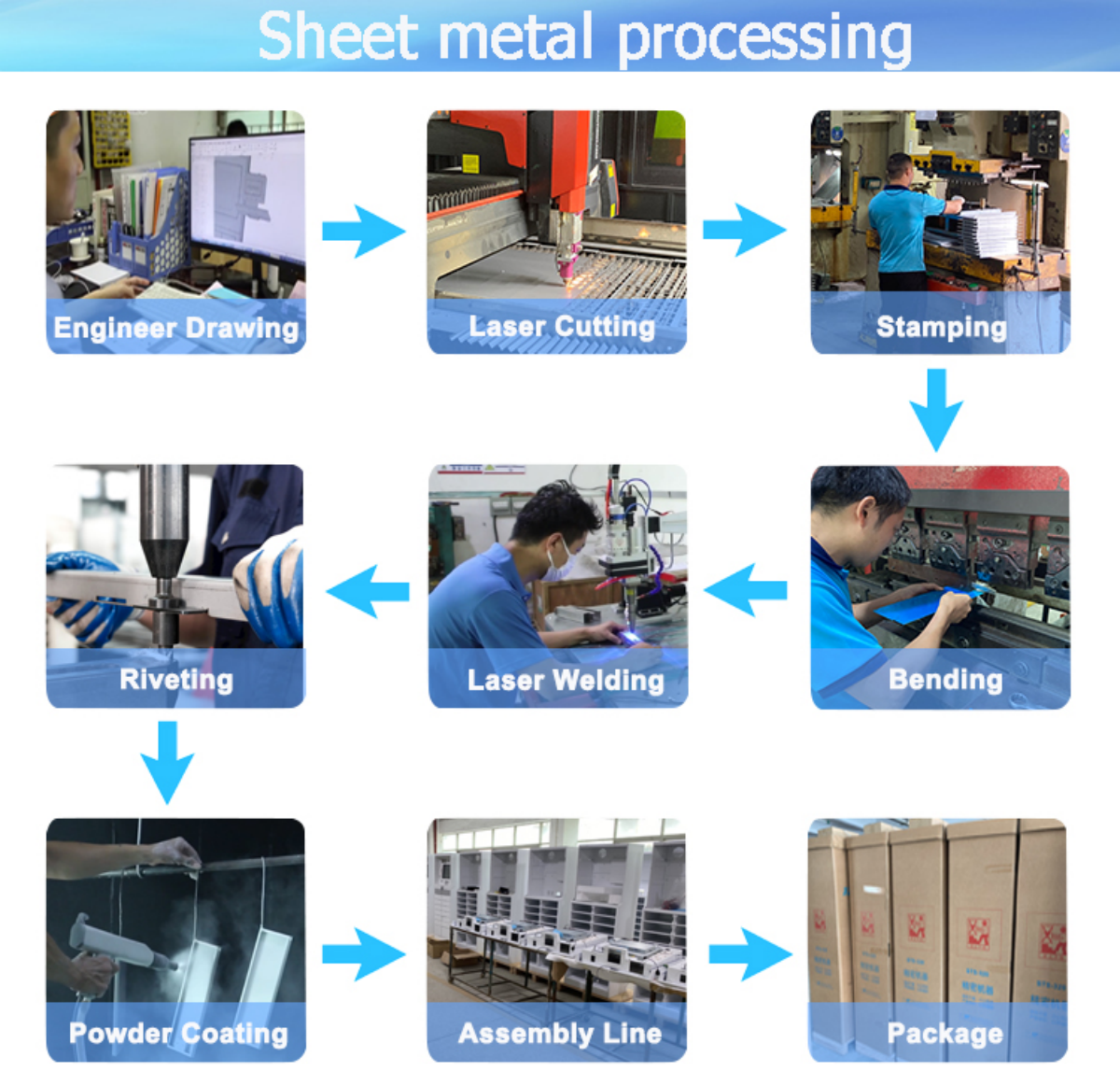

| Process: | Laser Cutting \Bending\ Welding |

| Surface treatment: | Painting\Powder Coating\Plating\Polishing |

| Tolerance: | Generally +/-0.1mm |

| Material: | aluminium/stainless steel/ galvanized sheet |

| Material Thickness: | 1mm-50mm sheet metal Sheet |

| MOQ: | Small Orders Accepted |

| Equipment: | Laser Cutting Machine, bending machine |

| Drawing File: | 3D/CAD/DWG/PDF/STEP/STP |

| Package: | Customer Requriement |

Sheet Metal Fabrication

| Product Name: | Custom Aluminium enclosure sheet metal fabrication |

| Material Capacity: | Aluminum,Carbon steel,Mild steel,Cold roll steel,Hot roll steel |

| Stainless steel,SECC,SGCC,SPCC,SPHC,Other metal | |

| Material Thickness: | 0.1-16mm or customized |

| Surface Finishing: | Powder coating |

| Nickel plating,Anodic oxidation | |

| Chrome plating,Yellow zinc plated | |

| Electroless nickel plating | |

| Chemical conversion coating | |

| Zinc plating,Electroplating .ETC | |

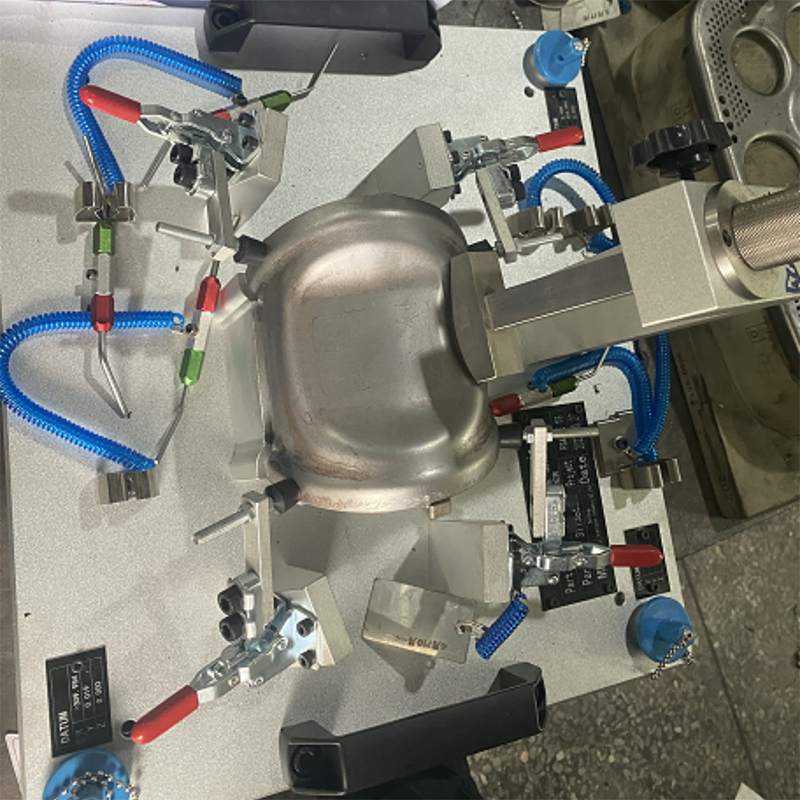

| Process Capability: | Metal fabrication, machining, welding, forming, shaping, punching, drilling, turning, milling, grinding, chip formatting, rolling, stamping, deep drawing, bending, spot or seam welding, spinning, forging, sand casting, die casting, investment casting, etc. |

| Professional level: | Sticking to the strict technical requirements to ensure the strength and accuracy of the product, professional technique negotiation, prompt production, guaranteed quality, 100% inspection, fast & convenient shipping logistics. |

| Samples service: | Available |

| Application | Auto parts, electronic products, power supply, industry cabinet, construction etc |

| Quality Control | (1) Material inspection--Check the material surface and roughly dimension. |

| (2) Production inspection--Each production section will check the key dimensions and appearance. | |

| Before surface treatment, do a good job of product packaging to avoid bumps and injuries. And check visual inspection | |

| (3) Sampling inspection--Check the quality before sending to the warehouse. | |

| (4) Pre-shipment inspection--100% inspected by QC assistants before shipment. | |

| Delivery: | Sample:7-15 working days |

| Bulk:20-30 working days (depend on the quantity) |

One-Stop Custom Precision Sheet Metal Fabrication Parts

RCT MFG provides OEM/ODM CNC machining, CNC milling, CNC turning, CNC lathe machining, sheet metal bending & stamping, plastic injection molds,rubber/silicone mold, injection molding, IML injection molding...etc customized plastic and metal components manufacturing service, with over 20 years of manufacturing experience team, only do middle above level quality products 100% according to customer CAD and requirements.

Our Sheet metal fabrication machines

FAQ

1. Are you a manufacturer or a trading company?

We are a 1500-square-meter factory located in Shenzhen, China.

2. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

3. Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

4. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

5. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

6. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production inspection--Each production section will check the key dimensions and appearance.

Before surface treatment, do a good job of product packaging to avoid bumps and injuries. And check visual inspection

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

7. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.