CNC Machining Parts

-

Customized High Precision CNC Machining Parts for Aquatic Products Testing Equipmen

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique a... -

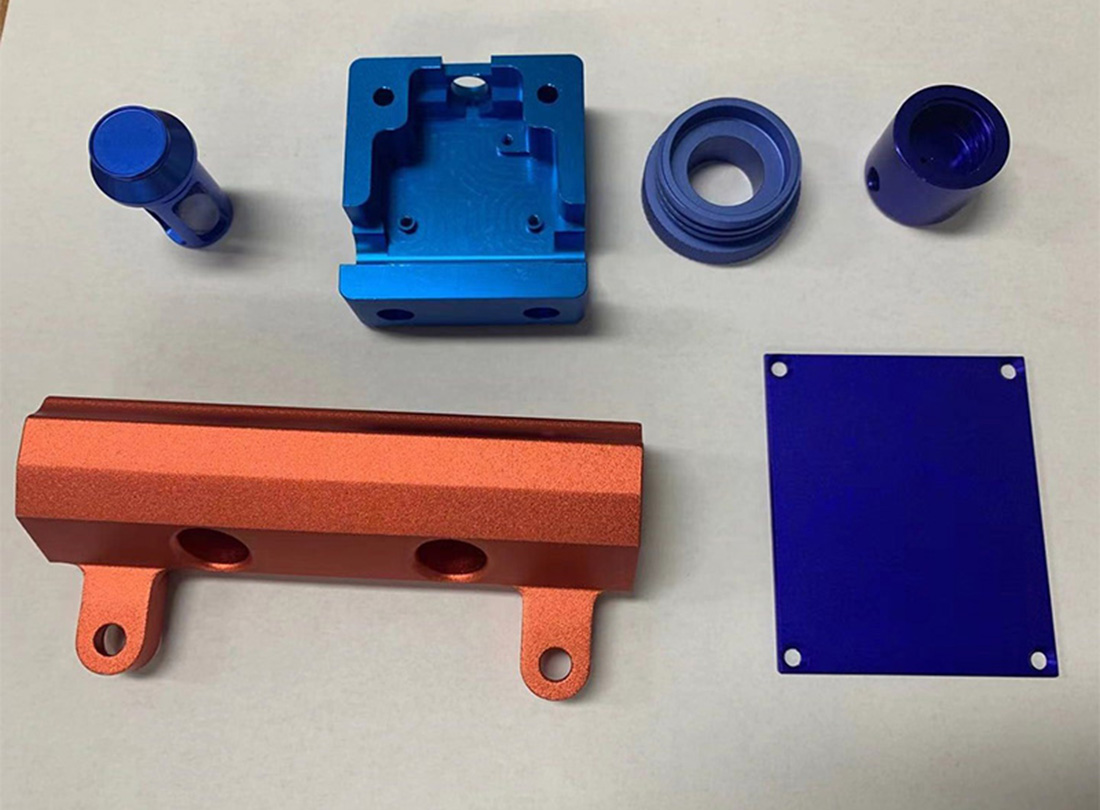

Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts

Material Aluminum 7075 Max. machining size 510 * 1020 * 500 mm(max) Tolerance according to 2D drawing requirment, normallly +/-0.05mm Surface Treatment Anodized (Type II Or Type III), chrome plating, silver plating, polishing, galvanized, electroplating, passivation, powder coating, spraying, and painting, etc Main Process CNC machining, turning, lathing, milling, drilling, grinding, boring, stamping, threading, tamping, EDM, wire walking, laser cutting, laser marking, an... -

Aluminum 6061 CNC machining Precision Parts for Electronics

What Are the Advantages of Aluminum 6061 CNC machining Precision Parts? High precision CNC machining is suitable for both one-off jobs and low-to-high volume production (from 500 up to 10,000 parts a week), due to its high repeatability. The main benefits associated with close tolerance CNC machine manufacturing, include: ● Extremely accurate ● High repeatability ● Achieves very tight tolerances ● Materials provide excellent and fully isotropic physical properties ● Suitable for most en... -

Precision anodized 7075 Aluminium Machined Wheels for Automative

Material Aluminum 7075 Max. machining size 510 * 1020 * 500 mm(max) Tolerance according to 2D drawing requirment, normallly +/-0.05mm Surface Treatment Anodized (Type II Or Type III), chrome plating, silver plating, polishing, galvanized, electroplating, passivation, powder coating, spraying, and painting, etc Main Process CNC machining, turning, lathing, milling, drilling, grinding, boring, stamping, threading, tamping, EDM, wire walking, laser cutting, laser marking, and surfac... -

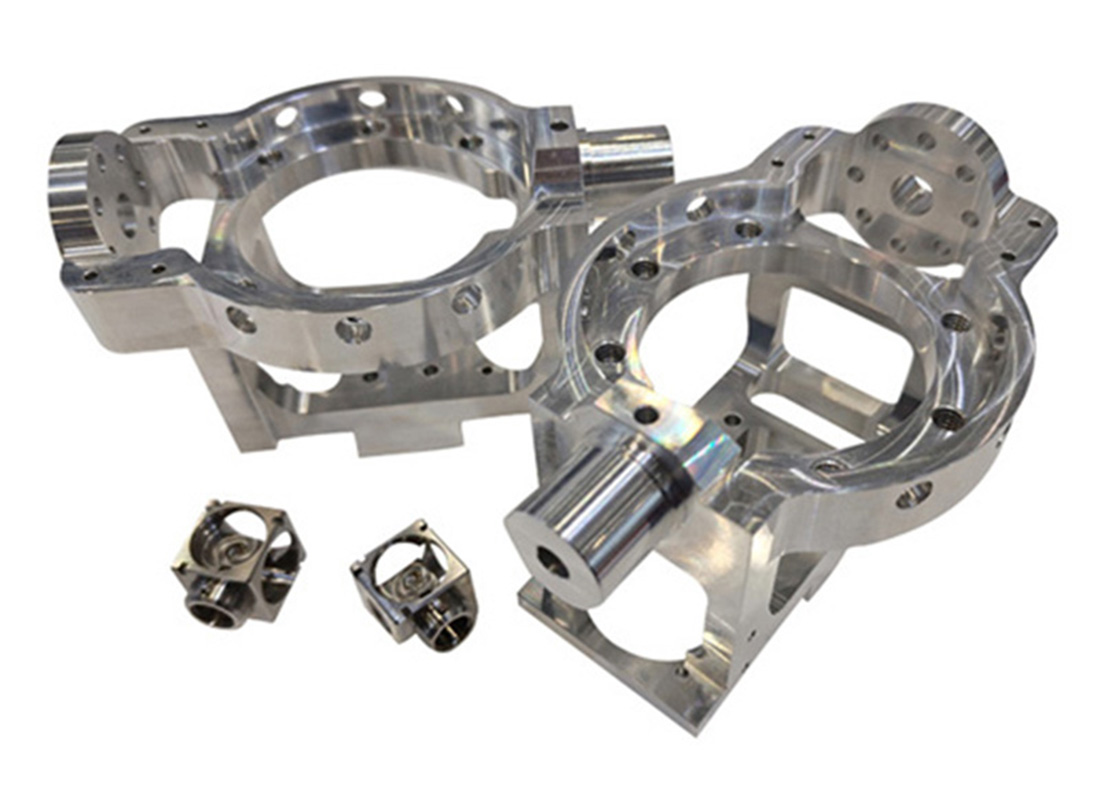

CNC Milling of High Precision Aluminum Machined Parts for the Process Fluid Circulation Industry

What Are the Advantages of Precision CNC Machining parts? High precision CNC machining is suitable for both one-off jobs and low-to-high volume production (from 500 up to 10,000 parts a week), due to its high repeatability. The main benefits associated with close tolerance CNC machine manufacturing, include: ● High repeatability ● Achieves very tight tolerances ● Materials provide excellent and fully isotropic physical properties ● Suitable for most engineering applications ● Cost-effect... -

CNC Machining of stainless steel housigg for the Gas Compression Equipment Industry

What Are the Advantages of Precision CNC Machining parts? High precision CNC machining is suitable for both one-off jobs and low-to-high volume production (from 500 up to 10,000 parts a week), due to its high repeatability. The main benefits associated with close tolerance CNC machine manufacturing, include: ● High repeatability ● Achieves very tight tolerances ● Materials provide excellent and fully isotropic physical properties ● Suitable for most engineering applications ● Cost-effect...