Benefits of Using CNC Machining for Aerospace Parts

The many advantages of computer numerical control (CNC) machining make it an ideal fit for aerospace part production. Its benefits include:

Superior performance. To safeguard against part failure, aerospace components must adhere to stringent dimensional, tolerance, and performance requirements. CNC machining is ideal for this, making it possible for manufacturers to use high-performance yet difficult-to-machine materials like titanium in production.

Light weight. For equipment that takes flight, weight is an important consideration in its parts. CNC machining is capable of producing thin-walled components and structures from lightweight yet strong materials to fulfill this need.

High efficiency. One CNC machine can complete several machining processes. Also, through automation, CNC machining achieves higher speeds to shorten production cycles and improve efficiency.

Reliable precision. Thanks to continuous improvement in CNC machining, the process is increasingly precise. Better accuracy and process control minimize manufacturing defects and result in durable, high-quality parts with tight tolerances.

Affordability. Precision combined with rapid production helps with per-part costs, saving money on material waste, defect rework, and labor. Improved output also boosts profitability.

At RCT MFG, we offer high precision machining parts of the aerospace industry, including interior aircraft components, drone components, wiring organization components, and many others. We rise to the challenge of crafting high precision components designed for modern flight vehicles, while consistently maintaining the rigorous standard of on-time delivery and reliable quality we’ve upheld for over 10 years.

Our Aerospace Machining Advantages

1. Leading manufacturers of aerospace components.

2. Our modern CNC machining fully meets the stringent needs of the diverse customer base of the aerospace industry by providing close-tolerance (0.001mm), precision-machined components.

3. We work with a broad array of plastics, metals, alloys, including commonly used materials such as aluminium and titanium.

4. Specialized technicians along with veteran engineers rigorously monitor every stage of the aerospace machining process.

5. We render complete services from concept/design development to manufacturing, including heat- treating, plating, painting, testing, precision cleaning, and finishing.

6. We have strict privacy policies and we manage export-controlled projects with extreme security.

Aerospace Machining Materials

| METALS | PLASTICS |

| Alloys | PVC |

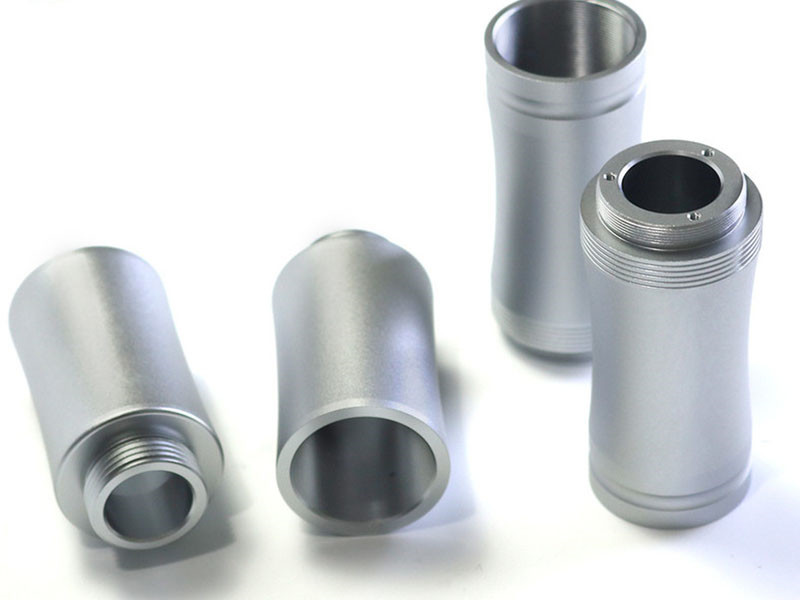

| Aluminum | Nylon |

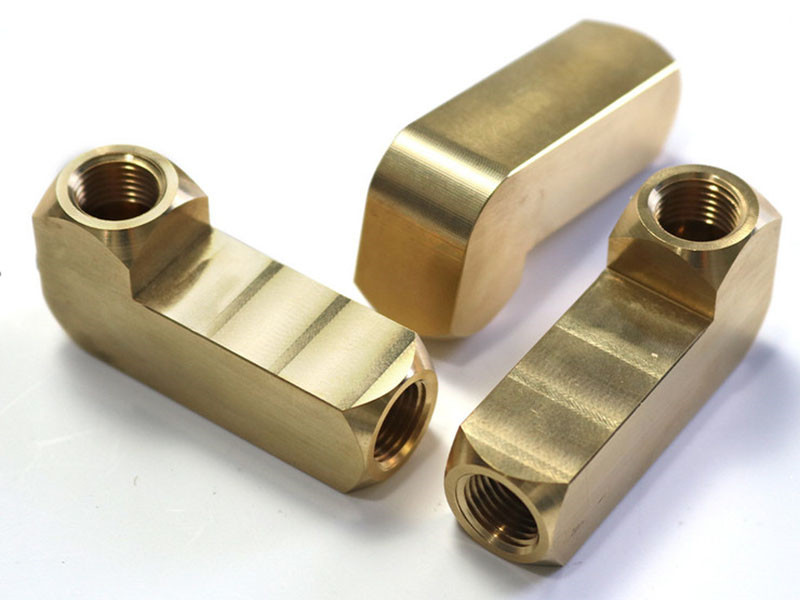

| Brass | Delrin |

| Copper | PTFE |

| Stainless Steel | UHMW |

| Precision Steel | Ultem |

| Titanium | PEEK |

| Special Alloys | Acetal |

Aerospace Milling with 5 Axis CNC

As the aerospace industry evolves into more complex machined parts, RCT's 5-axis machines enable large workpieces to be easily loaded that often don't fit easily to a 3 or 4-axis operation. From the highly rigid platform to the flexible tilt/swivel spindle, RCT's 5-axis machines combine the stability and versatility that shop owners look for and need when machining parts with complex geometry in a single setup.

Aerospace Machining product shows

Aerospace CNC Parts

Aerospace CNC Parts

Aerospace CNC Parts

5axis Aerospace CNC Parts

PEEK Aerospace CNC Parts

Machining turning milling composite parts